THE DIFFERENCE OF CHAMELEON FILM AND NANO CERAMIC FILM

The key differences between Chameleon Window Film and Nano-Ceramic Film:

Chameleon Film: Utilizing an optical coating, it automatically changes color with light (e.g., a gradient of blue, purple, or green). Its vibrant colors and aesthetic appeal make it ideal for those seeking personalized car features. Nano-Ceramic Film: Using ceramic particles to block heat, it contains no metal and does not oxidize, resulting in a higher insulation rate (up to 90%) and a longer lifespan (5-10 years), making it ideal for those who prioritize practicality.

What are the differences between different types of window film?

| Type | Core Structure Characteristics | | Applicable Scenarios |

| Dyed Film | Only dye layer + glue layer | 1-1.8mil | Low-end model, limited budget |

| Metallic Film | Multilayer metal + polyester substrate | 2-3mil | In high temperature areas, pursue high insulation |

| Nano Ceramic Film | Nano-ceramic particles + PET layer | 2-4mil | High-end models with signal penetration |

| Privacy Film | Dark dye layer + one-way perspective technology | 2-3mil | Commercial/luxury cars, privacy oriented |

| Chameleon Film | Colorful gradient, highly personalized | 2-3mil | Commercial/luxury cars, privacy oriented |

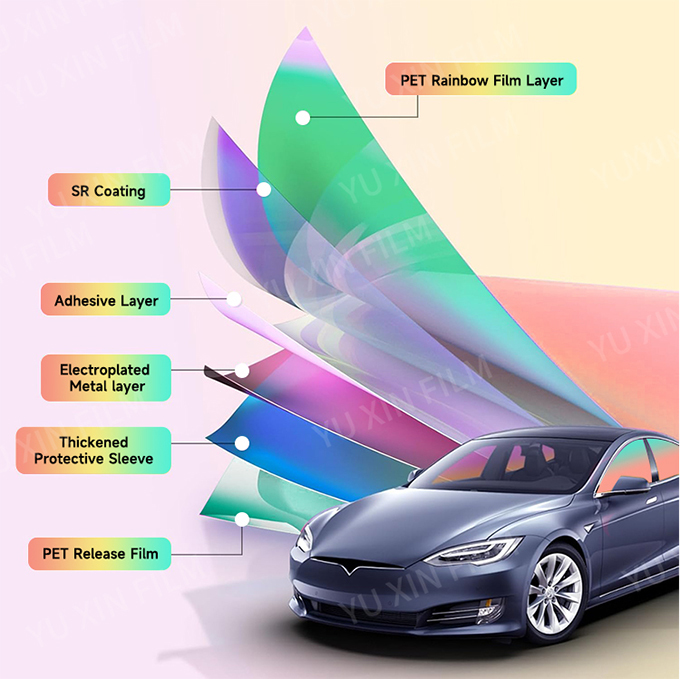

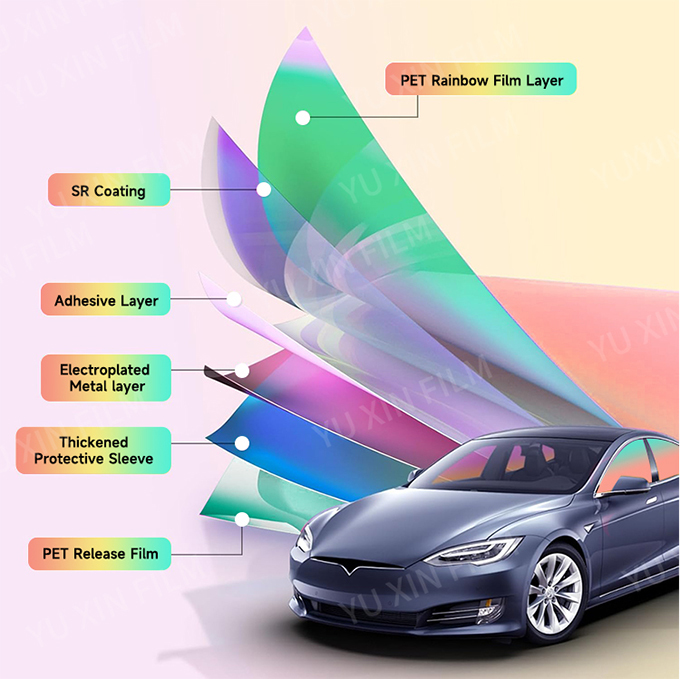

The main structure of car window film

Chameleon automotive window film utilizes a multi-layer nanocomposite structure:

1. The base layer utilizes high-toughness PET polyester film, providing fundamental strength and stability.

2. The metal oxide coating layer, deposited using a magnetron sputtering process, utilizes materials such as indium tin oxide to achieve a light interference color-changing effect.

3. The UV-absorbing layer utilizes a special nanomaterial that blocks 99% of UV rays.

4. The explosion-proof adhesive layer utilizes a high-molecular polymer colloid to enhance the glass's impact resistance.

5. The wear-resistant coating is surface-hardened for enhanced scratch resistance.

What are the benefits of car window film?

Dynamic Aesthetics: A dazzling gradient of blue, purple, and green changes color depending on the lighting angle, instantly enhancing the vehicle's appearance and recognition, making it a focal point on the road.

Intelligent Light Adjustment: Automatically adapts to bright sunlight and nighttime conditions, reducing glare and enhancing driving comfort and safety.

Efficient Thermal Management: The nano-ceramic layer blocks over 85% of infrared rays, reducing the interior temperature by 8-12°C and reducing air conditioning energy consumption by 20%-30%.

Full-Time UV Protection: 99% UV protection protects the driver and passengers' skin and prevents aging and fading of the interior.

Durable Quality: Magnetron sputtering technology ensures scratch and wear resistance, with a 5-8 year warranty and color stability far exceeding that of ordinary dyed films.

Safety and Compliance: The windshield's light transmittance of ≥70% complies with regulations, and the explosion-proof adhesive layer reduces the risk of glass splashing, ensuring driving safety.

How does chameleon film works?

Chameleon film creates its color-shifting effects through structural optics, not pigments. It contains microscopic, layered coatings (often alternating nano-scale films of materials like titanium dioxide and silicon dioxide). These layers act like a photonic palette, manipulating light via three key processes:

Light Interference: When light hits the layered structure, waves from different layers overlap. Some wavelengths reinforce each other (making colors visible), while others cancel out, depending on the layers’ thickness and the angle of light.

Angle-Dependent Reflection: As the viewer’s angle or light source changes, the path length of light through the layers shifts. This alters which wavelengths are reflected, causing colors to morph (e.g., blue to green or gold to purple).

Diffraction & Iridescence: The nano-structure scatters light into its spectral components, creating a rainbow-like effect similar to butterfly wings or oil slicks.

In short, chameleon film is a light-responsive optical device, using physics—not chemistry or heat—to produce dynamic, shimmering hues that adapt to light and perspective.

Chameleon Film and Environmental Sustainability

Chameleon film aligns with eco-conscious goals through thoughtful design and production practices. Many variants use recyclable polyester bases, reducing plastic waste at end-of-life, while water-based, solvent-free adhesives minimize VOC emissions during manufacturing and installation. Some manufacturers employ energy-efficient nano-layering processes that cut carbon footprints compared to traditional film production. Though not all chameleon films are fully biodegradable, their long lifespan (8–12 years) reduces replacement frequency, lowering resource consumption. Additionally, their solar control capabilities indirectly support sustainability by cutting HVAC energy use, reducing carbon emissions from buildings and vehicles. While niche in the green film market, chameleon film’s blend of durability, low toxics, and energy-saving potential makes it a progressively eco-friendly choice for design-forward projects.

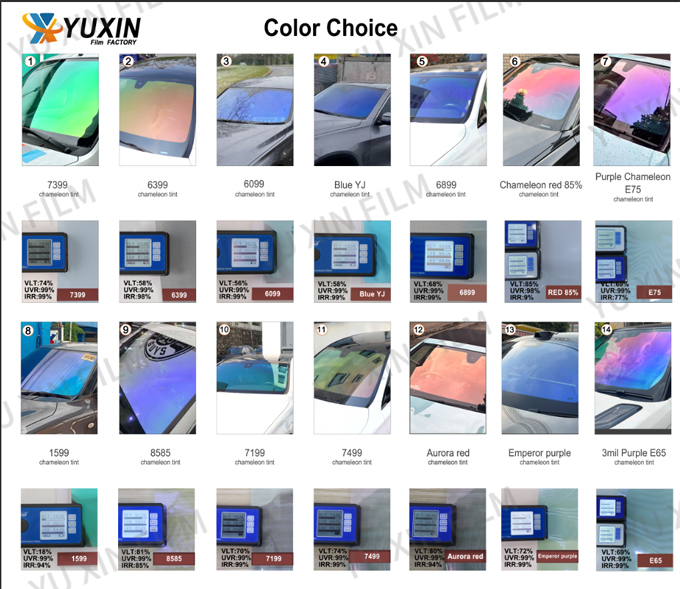

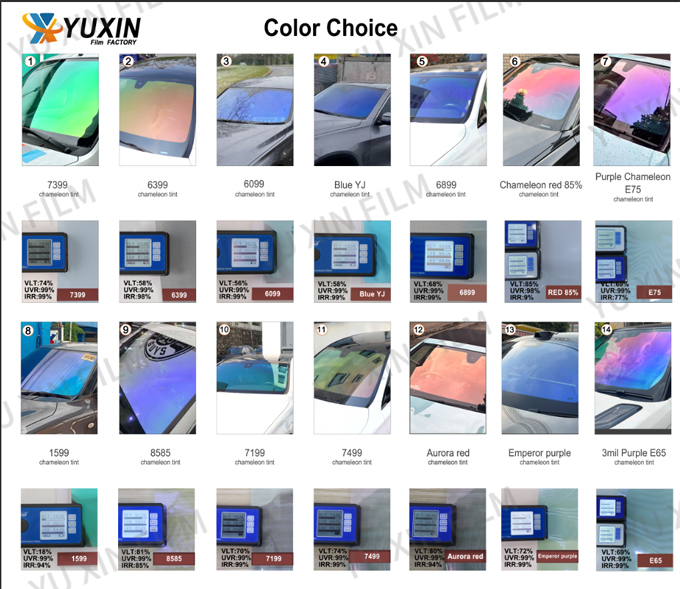

Color variety selection

14 colorful chameleon window films available in multiple colors, with light transmittance ranging from 20% to 90%. Customizable with high sun and heat protection! Inquiries welcome. Professional installation available. 5-10 year warranty.

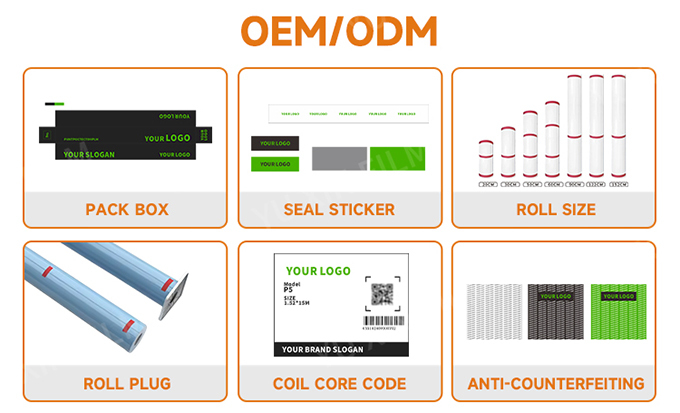

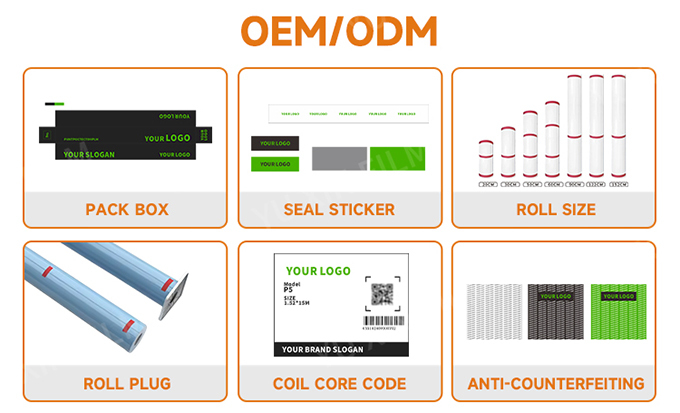

As a vertically integrated manufacturer, we control the entire production process—from functional masterbatch formulation to base film extrusion, coating application, slitting, and finished product assembly. This seamless supply chain ensures superior quality control, cost efficiency, and rapid customization for all paint protection film (PPF) solutions.

Equipped with top-tier fully imported TPU film production lines, we combine global precision with independent R&D upgrades to refine equipment performance. Our advanced machinery enables us to produce high-quality TPU base films with exceptional clarity, durability, and dust-free surfaces—critical for premium paint protection.

Our multidisciplinary team includes:

- Thermoplastic Elastomer Polymer Specialists: Optimizing material properties for superior adhesion, UV resistance, and self-healing performance.

- Mechanical Equipment Engineers: Ensuring precision in every production stage, from extrusion to coating.

- Production Technology Experts: Mastering processes to achieve uniform thickness, flawless surface finish, and consistent product quality.

- Dedicated QC Professionals: Conducting rigorous pre-shipment inspections to guarantee alignment with sample standards and dimensional accuracy (e.g., film length compliance).

Before shipment, our QC team meticulously verifies:

- Product-Sample Consistency: Ensuring every batch matches the approved prototype in texture, thickness, and performance.

- Spec Compliance: Checking film length, width, and mechanical properties to meet exact customer requirements.

- Dust-Free Purity: Maintaining cleanroom-grade production environments to eliminate surface imperfections.

With a large-scale warehouse stocked with TPU paint protection film, automotive window film, architectural decorative film, TPU windshield film, and colored PPF, we enable immediate order fulfillment. Our streamlined logistics ensure your products are delivered promptly, reducing lead times and enhancing supply chain reliability.

FAQ:

-

A1: High-quality products have a lifespan of approximately 3-8 years, while lower-quality dye-based films may fade in 1-2 years. A scratch-resistant coating on the surface reduces wear and tear.

A2: Not recommended! It requires a dust-free environment, specialized tools, and a heat gun to set the film. DIY applications can easily cause bubbles and warping.

A3: Use a neutral detergent and a soft cloth to clean. Avoid using alcohol or steel wool to prevent scratches on the coating.

A4: Vacuum coating technology deposits nanoscale metal oxides (such as TiO₂ and SiO₂) onto a PET substrate. When light passes through, it interferes with the film and reflects different colors.

A5: Many variants use recyclable materials (e.g., polyester bases) and low-VOC adhesives. Some brands offer energy-efficient production processes, though full biodegradability is rare.

A6: Light colors will not have an impact, but dark colors may slightly reduce visibility at night, subject to local light transmittance regulations. For windows with a VLT of 20% or less, it is recommended to install it on the side windows.

Product Tags:

|

|

Customized 85% VLT Red Purple Car Window Tint Film High Definition Chameleon Film Images

|